Flush Threaded PVC Casting and Slotting Pipe Specifications

All Driller’s Pipe Flush Threaded PVC pipe and screen products are manufactured from plastic of Type 1 Grade PVC compound with a cell classification of 12454-B per ASTM D1784. Pipe material are NSF approved for portable water and in strict compliance with ASTM D1785.

To maintain the integrity of the slotting and threading process, the only coolant used is air.

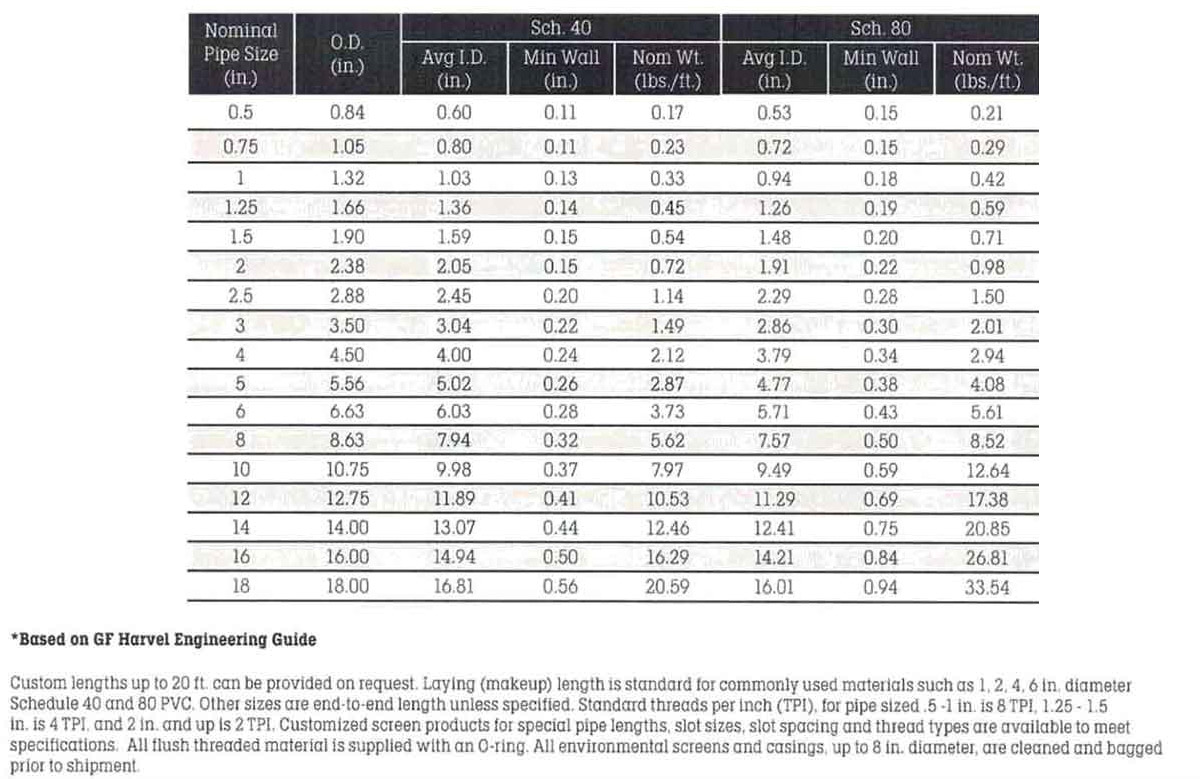

Physical Data For Common Size Pipe schedule 40, 80 and large diameter SDR17”

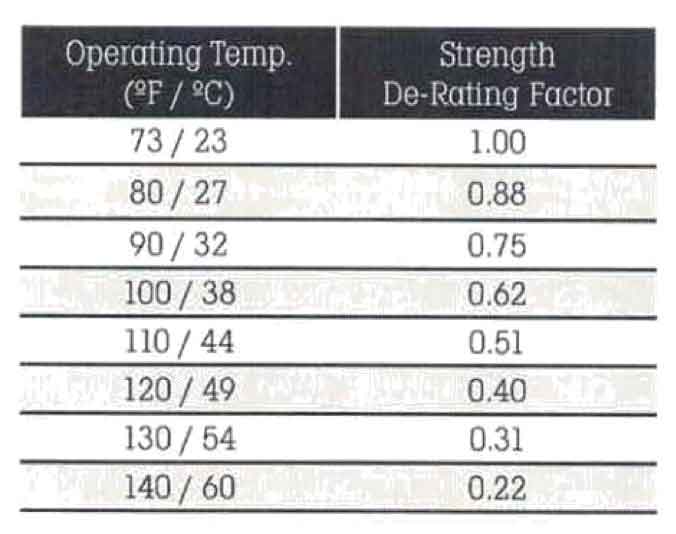

Temperature De-Rating Table

Curing of cement and grout generates sufficient heat to affect PVC strength and performance. When operating at elevated termperatures, the actual values for Collapse Pressure. Burst Pressure and Tensile Strength will be de-rated according to the chart.

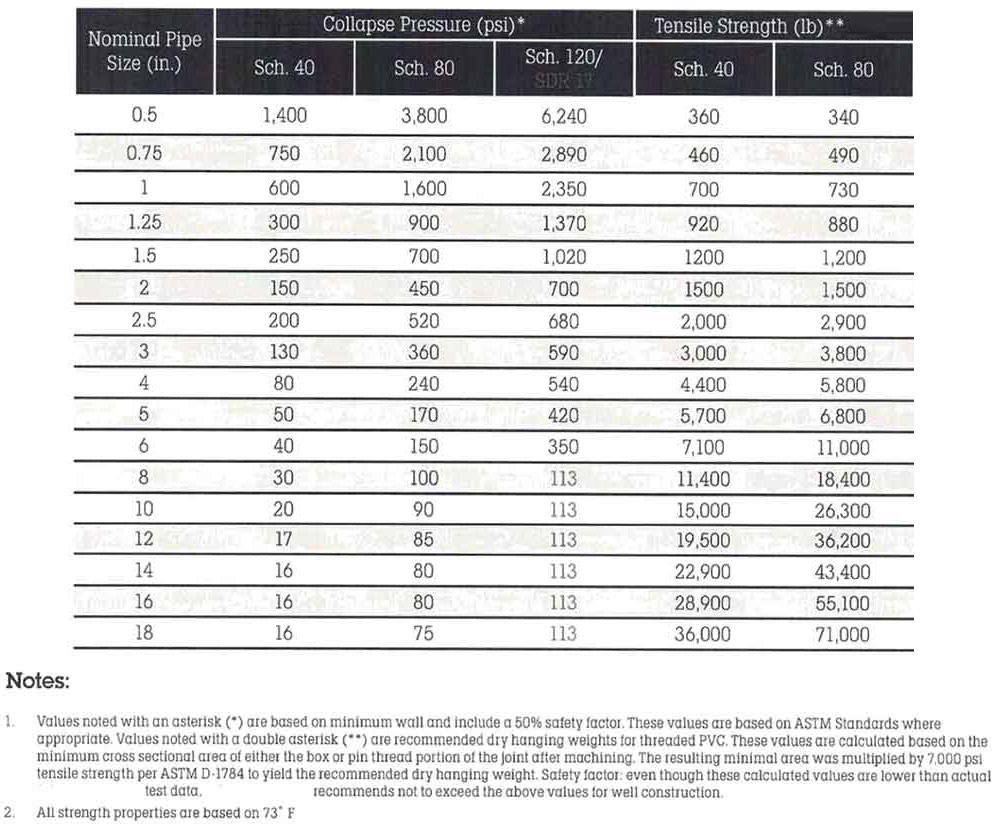

Pressure and Strength

Testing methods and procedures used are in compliance with ASTM F-480 standards for thermoplastic pipe in all applicable areas.

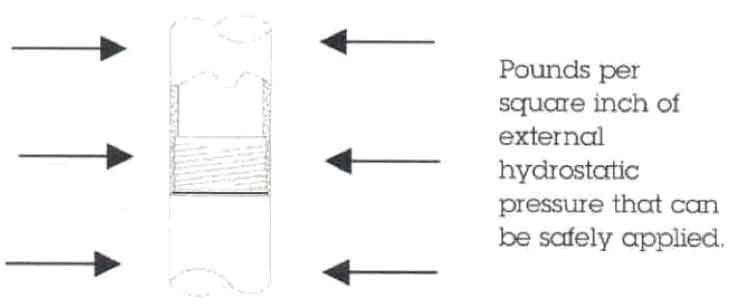

Collapse Pressure

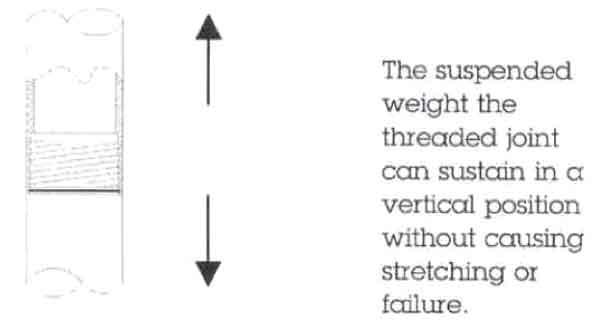

Tensile Strength

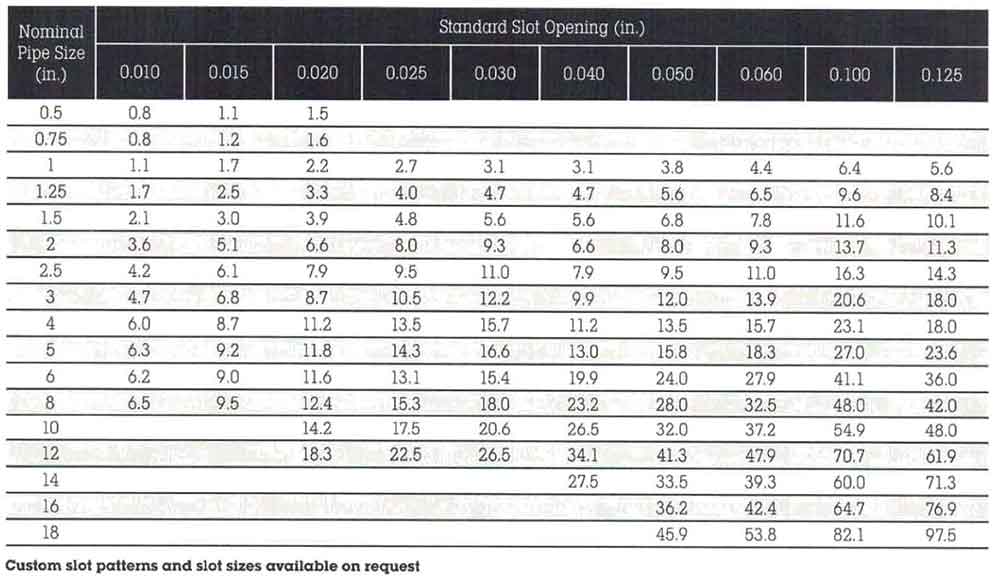

Slotted Screens and Open Area

The following tables represent the standard open area for the Driller’s Pipe slotted PVC well screen. All calculations are based on the inside diameter of the pipe which represents the most accurate area and transmitting potential of the screen.

The data represented in these tables is for standard product line, to calculate transmitting capacity in gpm at 0.1 ft/sec flow velocity. Multiply the open area of square inches by 0.31

Slotted Screens and Open Area in Square Inches Per Foot for Schedule 40 – Std. Construction

Among some of the fabricating options for casing and screen:

- Plain end, flush joint or NPT threaded

- Threaded products supplied in laying lengths

- Slot openings from 0.010 to 0.500 in.